Client Overview:

Our client is a leading precast contractor, renowned for delivering complex bridge structures and large-scale civil works projects. With decades of experience, they bring together precision engineering and efficient manufacturing to deliver durable, cost-effective infrastructure solutions across the globe.

Scope of Work of the Project:

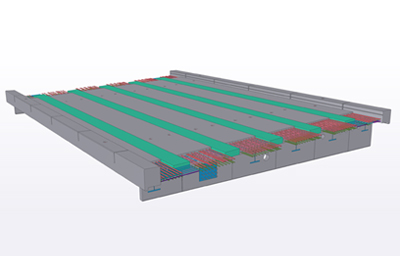

To deliver the construction model and drawings for a precast composite bridge deck. The detailed scope of work covered the following key activities:

- Development of the LOD 400 construction model from the design inputs

- Placement of connection components, embedded hardware, and lifting elements

- Model coordination with other trades, particularly the steel fabrication model

- Preparation of panel placement drawings (GA) and detailed production drawings

- Extraction of the Bar Bending Schedule (BBS)

The Challenges:

For this project, the client engaged Intec to develop a clash-free, composite model for the precast deck.

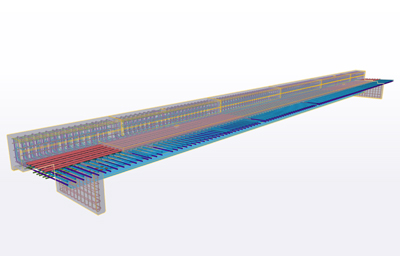

One of the main challenges in this project was to model the precast deck panels with very high precision, since these panels had to be cast on top of the structural steel sections as a composite system.

This steel surface was not flat but cambered, which made the alignment of panels even more complex. Any pre-casting error on the curved profile matching the camber could be hazardous in aligning the concrete curve with the supporting cambered steel member. Such misalignment could result in costly and time-consuming changes at the site.

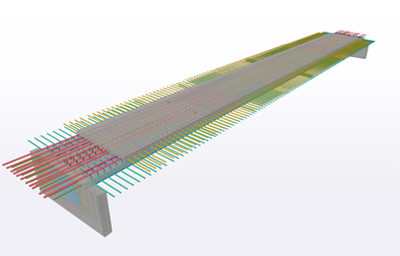

Additionally, dense reinforcement projections acting as dowels for adjacent, to be connected slab layouts were to be modeled with high precision for a perfect interface match between precast panels and cast-in-situ stitches. Proper detailing and clash-free arrangement of these rebars were critical to ensure smooth execution without unwanted site intervention or incorporation during construction.

Our Role in the Success of the Project:

To address these challenges, our team used Tekla Structures to build the entire precast system with high precision. Our approach included:

- Parametric Modeling for Flexibility We developed parametric components throughout the project - allowing panel dimensions, placements, and quantities to be easily adjusted based on the requirements.

- Structural Steel Fabrication for Detailed Accuracy We inserted the steel fabrication model into our environment to verify if the alignment of the precast panels matched precisely with the cambered steel sections. All rebar projections, connection hardware, and lifting hooks were reviewed against tight tolerances so that no on-site conflicts could arise at the time of installation.

- Trimble Connect for Real-Time Collaboration We utilized Trimble Connect to share progress models with the overseas design team, enabling on-time feedback and markups. This accelerated the review cycle, reduced turnaround times, and kept all teams aligned across borders.

We utilized Trimble Connect to share progress models with the overseas design team, enabling on-time feedback and markups. This accelerated the review cycle, reduced turnaround times, and kept all teams aligned across borders.

Outcome & Impact:

We helped deliver a highly accurate, clash-free construction model of the precast composite bridge deck, which made on-site execution much smoother. Early coordination with the steel fabrication model and using Trimble Connect for real-time collaboration with the design team abroad reduced errors and avoided costly on-site corrections. This approach saved time, improved efficiency, and ensured better coordination between all teams.

This project stands as a strong example of how digital construction and BIM coordination can significantly improve the quality and speed of infrastructure delivery - especially for complex precast systems.

Project Info

| Client | Project Type | Duration | Built Area | Services Provided | Platforms Used | Special Highlights |

| Leading precast contractor | Infrastructure – Composite Bridge Deck | 2 Months | 1.7 hectare | BIM (Structure), LOD 400 Modeling, Drawings, BBS | Tekla Structures, Trimble Connect | Cambered steel coordination, clash-free rebar detailing, and real-time collaboration |