MEPF Detailed Design Services

In the construction industry, MEPF (Mechanical, Electrical, Plumbing and Fire Protection) design services play a crucial role in ensuring the efficient and seamless integration of various building systems. These services are essential for creating comfortable, safe, and energy-efficient spaces that meet the diverse needs of occupants.

What are MEPF Design Services?

MEPF design services offer a holistic approach to the planning, design, and coordination of mechanical, electrical, and plumbing systems in buildings and facilities. Our team of specialized trade-specific design engineers collaborates to create tailored solutions that align with the intended use of the structure, optimizing its systems and services. From HVAC systems to electrical distribution and plumbing networks, our MEPF design services ensure seamless integration, efficiency, and compliance with industry standards, resulting in high-performing, sustainable, and safe built environments.

Importance of MEPF Design in Construction

MEPF design is the backbone of a successful construction project, influencing every aspect of a building's functionality and performance. By meticulously integrating heating, ventilation, and air conditioning (HVAC) systems, electrical systems, and plumbing systems, MEPF design optimizes energy efficiency, reduces environmental impact, and fosters a healthier indoor environment. From ensuring proper air circulation and temperature control to maximizing resource utilization, a well-executed MEPF design enhances occupant comfort, safety, and productivity, while minimizing operational expenses and carbon footprint.

Understanding MEPF Design Services

Definition of MEPF MEPF stands for Mechanical, Electrical, and Plumbing, representing the three main systems that are integrated and coordinated through MEPF design services.

Our MEP Detailed Design Services Includes:

Intec Infra, with an expert team of design engineers, has the capability to offer design assistance services across Mechanical, Electrical, Plumbing, and Fire Protection (MEPF) engineering disciplines. These detailed design services are tailored to meet specific project requirements and comply with various international codes and standards, including NFPA, NEC, BS 7671, IEEE, IEC, IPC, and ASHRAE.

Intec Infra's design assistance services require clients to provide applicable building codes and parameters before commencing the design work, ensuring compliance with local and international standards.

Mechanical Design Services

- Heat load calculations

- Ventilation calculations

- Static pressure calculations

- Air flow diagrams

- Heating, cooling, and ventilation schematics

- Sizing of ducting, piping, and HVAC equipment (boilers, chillers, air handling units, etc.)

- Utilized software: Elite Chvac, HAP, McQuay Duct Sizer and Pipe Sizer, Excel Spreadsheets, Trane-Trace 3D Plus

Plumbing Design Services

- Water supply and drainage calculations

- Pipe sizing with fixture units

- Water supply and drainage schematic diagrams

- Domestic water and drainage layout drawings

- Pump head calculations

- Utilized software: Excel Spreadsheets

Fire Protection Design Services

- Sprinkler layout and pipe sizing per NFPA standards

- Fire protection schematic diagrams

- Hydraulic calculations for sprinkler systems per NFPA

- Utilized software: Excel Spreadsheets, Elite Fire

Electrical Design Services

- Design basis reports

- Conceptual and space planning (generator and transformer yard allocation)

- Lighting calculations (normal and emergency)

- Electrical load calculations and switchgear sizing

- Transformer, UPS, and generator sizing

- Short-circuit current calculations

- Cable schedules with voltage drop calculations

- Load balancing sheets

- Riser schematic diagrams

- Single-line diagrams (SLDs)

- Grounding, lightning protection, and bonding designs

- Fire alarm system designs

- Access control system designs

- Public address and voice alarm (PAVA) system designs

- Electrical schematic diagrams

- Earthing schematic diagrams

- Final design reports

- Utilized software: Dialux/Dialux EVO (lighting calculations), ETAP, and Excel (electrical calculations)

Integration of MEPF Systems One of the key aspects of MEPF design services is the coordination and integration of mechanical, electrical, and plumbing systems. This ensures that the systems work seamlessly together, optimizing energy efficiency, reducing operational costs, and minimizing potential conflicts or clashes during construction.

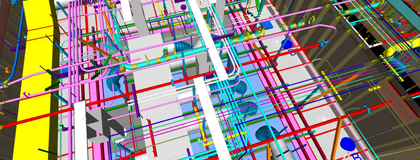

BIM in MEPF Design In modern times, modelling of MEPF services at design stages into Revit to create BIM is crucial and of great value for the extended design teams. The idea here is to firstly have a better communication of the design between the teams and to have a strong coordination at the design stages to deliver a conflict free and constructable model to the General Contractor to construction the building. Hence, Intec Infra stresses on the fact to design in Revit at the concept stage itself, till the Tender stage (LOD 300) model delivery to the General Contractor.

Benefits of MEPF Design Services

- Improved Efficiency Properly designed MEPF systems contribute to the overall efficiency of a building, reducing energy consumption and operating costs. Optimized systems also ensure better indoor air quality and thermal comfort for occupants.

- Cost Savings Effective MEPF design can lead to significant cost savings throughout the building's lifecycle. Efficient systems minimize energy usage, reduce maintenance requirements, and extend the lifespan of equipment.

- Enhanced Safety MEPF design services prioritize safety by incorporating fire protection systems, emergency power systems, and complying with relevant building codes and regulations. This ensures the safety of occupants and protects the building from potential hazards.

Challenges in MEPF Design Services

Complexity of Systems

The integration of various MEPF systems, each with its own intricate components and requirements, presents a significant challenge. Coordinating these systems while considering factors such as building layout, energy efficiency, and occupant comfort requires expertise and careful planning.

Regulatory Compliance

MEPF design services must adhere to local, national, and international building codes and regulations. Staying up-to-date with constantly evolving standards and ensuring compliance is a crucial aspect of MEPF design.

Innovations in MEPF Design Services

Sustainable Design Practices

Sustainable design practices are becoming increasingly important in MEPF design services. This includes the integration of renewable energy sources, such as solar panels and geothermal systems, as well as the implementation of energy-efficient technologies and materials.

Smart Building Technologies

The integration of smart building technologies, such as building automation systems, energy management systems, and Internet of Things (IoT) devices, is transforming MEPF design. These technologies enable real-time monitoring, control, and optimization of building systems, leading to improved energy efficiency and occupant comfort.

Renewable Energy Integration

The integration of renewable energy sources, such as solar photovoltaic (PV) systems, wind turbines, and geothermal systems, is becoming increasingly prevalent in MEPF design services. These renewable energy solutions not only contribute to sustainability goals but also offer long-term cost savings and energy independence.

Digital Twins and Predictive Maintenance

The concept of digital twins, virtual replicas of physical assets, is gaining traction in MEPF design services. Digital twins enable real-time monitoring, predictive maintenance, and optimization of MEPF systems, leading to improved efficiency, reduced downtime, and extended equipment lifespan.

Modular and Prefabricated Systems

The use of modular and prefabricated MEPF systems is an emerging trend that can streamline construction processes and reduce on-site installation time. Prefabricated components are manufactured off-site under controlled conditions, ensuring consistent quality and minimizing waste.

MEPF Design Services - Takeaway

To sum it up , MEPF design services are essential for integration of mechanical, electrical, and plumbing systems in buildings design process along with other trades such as Architecture, Interior Design, Structure, Civil, Landscape, Façade, etc. These services contribute to improved efficiency, cost savings, enhanced safety, and occupant comfort. By leveraging expertise, innovation, and emerging technologies, MEPF design service providers play a crucial role in creating sustainable, energy-efficient, and functional buildings that meet the diverse needs of occupants.

Final Thoughts As the construction industry continues to evolve, MEPF design services will remain at the forefront of creating high-performance buildings that prioritize sustainability, occupant well-being, and operational efficiency. By collaborating with experienced and innovative MEPF design service providers, project stakeholders can unlock the full potential of their buildings and contribute to a more sustainable and resilient built environment.

FAQs

What is the difference between design calculations, design development, and design drafting in MEPF design services?

In the realm of Mechanical, Electrical, Plumbing, and Fire Protection (MEPF) design services, these three components play distinct roles in the overall design process:

Design Calculations:

Design calculations are the mathematical and analytical processes involved in determining the appropriate sizing, capacities, and specifications of MEPF systems and components. These calculations are performed by engineers and involve various formulas, equations, software tools, and computational methods based on established codes, standards, and best practices. Examples of design calculations include heat load calculations, ventilation calculations, electrical load calculations, pipe sizing calculations, and hydraulic calculations for sprinkler systems.

Design Development:

Design development is the stage where the conceptual design is refined and detailed. It involves creating schematic diagrams, layouts, and drawings that illustrate the proposed MEPF systems and their integration within the building or facility. During this phase, engineers and designers work closely to ensure the systems are properly coordinated, optimized for efficiency, and comply with relevant codes and regulations. Design development deliverables may include schematic diagrams for HVAC, plumbing, electrical, and fire protection systems, as well as preliminary equipment selections and specifications.

Design Drafting:

Design drafting, also known as drafting or detailing, is the process of creating detailed construction documents that translate the design intent into design and construction drawings and specifications. Skilled drafters and BIM modelers use specialized software tools to produce detailed plans, sections, elevations, and 3D models that clearly communicate the layout, dimensions, and installation requirements of MEPF systems. Design drafting deliverables may include detailed floor plans, reflected ceiling plans, equipment schedules, riser diagrams, single-line diagrams, and construction details for MEPF systems.

In summary, design calculations provide the technical foundation for system sizing and selection, design development translates the conceptual design into schematic diagrams and layouts, and design drafting transforms the developed design into detailed construction documents for implementation. These three components work together seamlessly to deliver comprehensive MEPF design solutions that meet project requirements, code compliance, and ensure the efficient integration of various building systems.